What is the Rebound Hammer Test for Concrete?

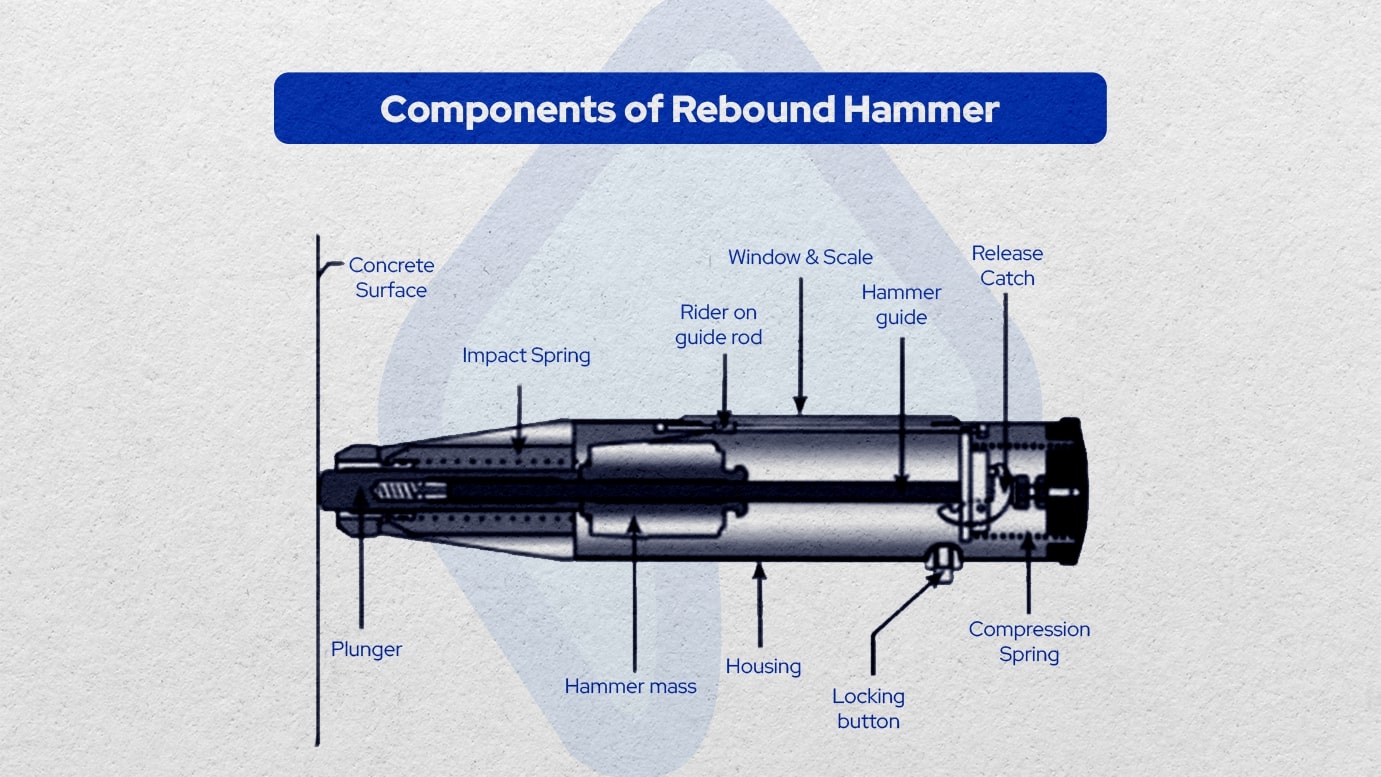

There are two ways of testing concrete for its compressive strength. Firstly, the destructive way in which the concrete has to be broken and secondly, the non-destructive way in which concrete is tested without damaging it. The rebound hammer test for concrete is a non-destructive process that provides the indicative compressive strength of the concrete structure. It is a convenient and quick process. This test is also called the Schmidt hammer test and consists of a spring controlling a mass sliding on a plunger housed in a tubular arrangement.

The rebound hammer system follows a specific mechanism to check the compressive strength of the concrete structure. The plunger present inside the rebound machine is pressed against the concrete surface. The spring controlled mass hits the concrete surface with constant energy. The mass controlled by a string after hitting the concrete surface rebounds off. The extent of the rebound is a measurement of the concrete surface hardness, measured on a graduated scale.

The graduated scale gives a Rebound number/index signifying the compressive strength of the concrete. A concrete component that is adequately stiff and strong absorbs low energy to yield a higher rebound value.

What is the Purpose of the Rebound Hammer Test?

The test process explaining the rebound hammer test has been explained precisely in the IS 13311(2)-1992. The various objectives of this test as per the code are:

1. To calculate the compressive strength of concrete by establishing a relation between the rebound value and the compressive strength.

2. To check whether the concrete is uniform or not.

3. To examine the quality of concrete based on the regulations given in the above code.

4. To define a relation between one property of concrete with another.

5. This test assists to find which part of the concrete structure is weak or which of the two building structures is unsound.

What is the Principle of the Rebound Hammer Test?

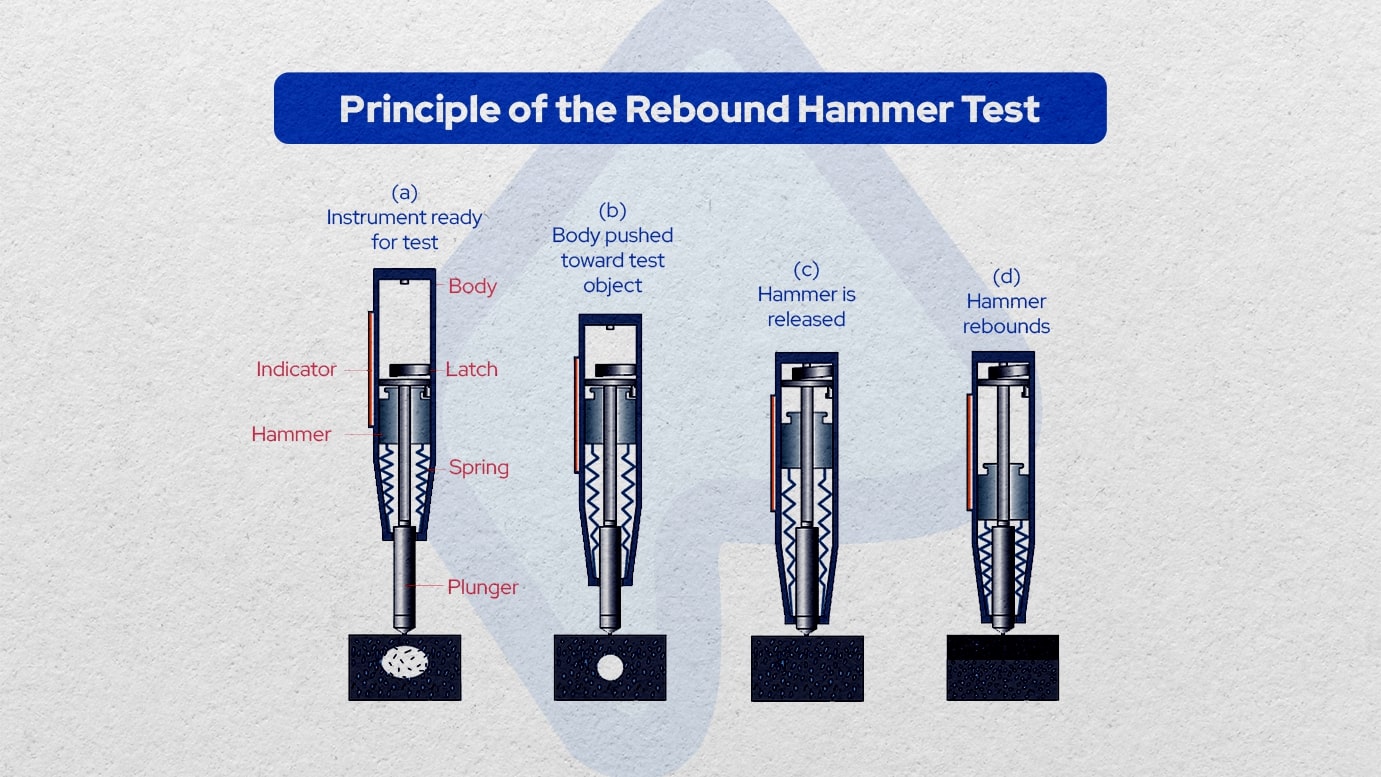

The principle of the elastic hammer test is: "The rebound of an elastic mass on the concrete surface depends on the hardness of the concrete surface on which the mass strikes". The spring-driven mass in the elastic hammer will rebound when the plunger forces against the concrete surface. The amount of recovery depends on the hardness of the concrete surface.

Therefore, to calculate the compressive strength of concrete, the stiffness of the concrete structure and the rebound value are correlated. The rebound value is read from a graduated scale where it is expressed as a number or a rebound index. For ease of use, concrete compressive strength is recorded directly from the chart provided on the hammer.

What is the procedure for Rebound Hammer Test?

It is essential to calibrate the rebound hammer tool before using it to test a concrete section. The hammer is tested against a test anvil made from steel to calibrate the rebound hammer. The steel anvil has a Brinell hardness number approximately equal to 5000N/mm2. After successful calibration against the test anvil, the rebound hammer is pressed against the concrete surface orthogonally to take the readings from the graduated scale in the hammer itself.

The hammer is kept horizontal against vertical surfaces and vice versa. When we align the hammer at any alternative angle other than 90o against any surface gives a different value for the same concrete.

The rebound value varies with the type of application. Approximate impact energies are different for different surface applications. Some average impact energy levels are given below for various applications:

1. Normal Weight Concrete - 2.25

2. Light Weight Concrete - 0.75

3. Mass Concrete Testing - 30.00

Precautions for Rebound Hammer Test

Here are some precautions that must be followed while performing the rebound hammer test:

1. Before testing the concrete surface, it should be smoothened, cleaned and dried.

2. In the presence of loose particles on the testing surface, the surface should be scraped using a grinding wheel before testing with the hammer.

3. Rebound hammer is not used on rough surfaces because the concrete may be suffering from loss of grout, improper compaction, spalled surface or tooled concrete surface.

4. The point where the rebound hammer strikes should be more than 20mm away from the edges or discontinuity in shape.

5. To improve accuracy, at one single point of testing on the concrete surface, six minimum readings are taken. The average of the six values gives the rebound number for the particular point on the surface.

Advantages of Rebound Hammer Test

Here are a few advantages of the rebound hammer test:

1. It is a type of tool that is easy and ready to use.

2. The rebound hammer indicates the uniformity properties of the concrete surface.

3. Schmidt’s hammer is an inexpensive tool.

4. This tool is used in rehabilitation projects for old structures.

Disadvantages of Rebound Hammer Test

The rebound hammer test also has some disadvantages that are:

1. The rebound hammer indicates the compressive strength of a local point.

2. The rebound value does not relate to the strength and deformation characteristic of the concrete surface directly.

3. The probe and spring arrangement inside the rebound hammer requires regular cleaning and maintenance.

4. Concrete defects are not accurately detected.