What is the difference between pre-tensioning and post-tensioning?

Concrete can take up the tensile stresses of steel and compressive stresses in ordinary reinforced concrete. The concrete below the neutral axis is ignored as it has weak tension.

Steel can withstand tensile stress, but concrete in the zone of tensile strength develops tiny cracks. The load-carrying capability of these concrete Sections can be increased by stressing both concrete and steel before applying external loads.

It is the concept of prestressed cement concrete. According to the ACI committee, prestressed concrete is concrete that has internal stresses of a suitable magnitude so that external loads are mitigated to the desired degree.

Prestressing Processes

Prestressing of heavy beams can be done in two distinct ways, External and Internal prestressing.

1. External Prestressing

This method isn't often used, which adjusts the external reactions by introducing different support conditions. This prestressing uses a simply supported beam that is externally prestressed by Jacks. Externally pressing requires precision in planning and execution.

2. Internal Prestressing

This system uses a prestressing force on the high-tensile steel, i.e., steel reinforcement. This process causes internal compressive stresses to concrete. Because of its simplicity and accuracy, this is the most popular method.

Internal prestressing can be achieved through Pre tensioning and post-tensioning of beams.

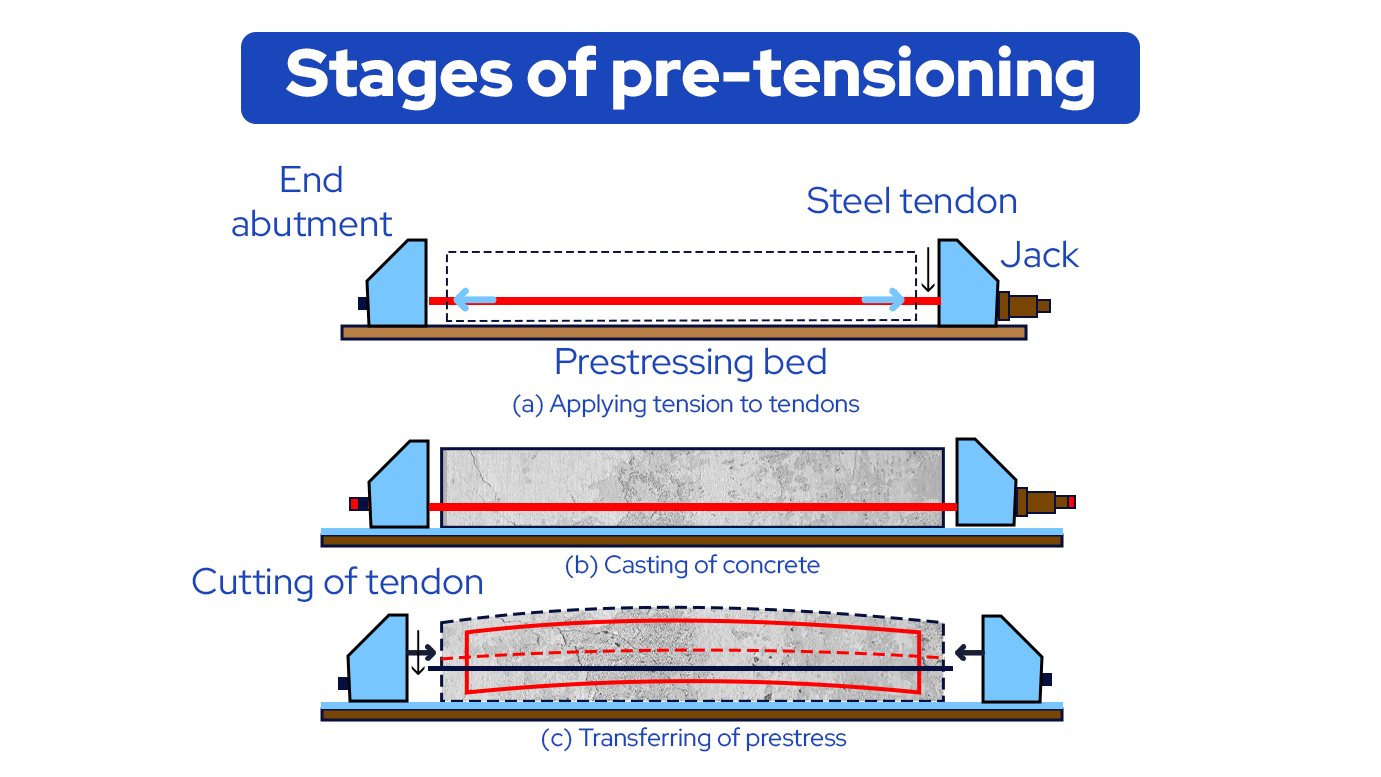

Pre tensioning

Pre-tensioning is when the steel tendons are tensed before concrete is cast. After the concrete is placed, the tendons are temporarily anchored against abutments. Then they can be cut or released.

The prestressing forces are transferred to the concrete through the bond along the lengths of the tendon. Pre-tensioning is done in precasting facilities in permanent beds. These plants produce pre-tensioned concrete elements for use in the building industry.

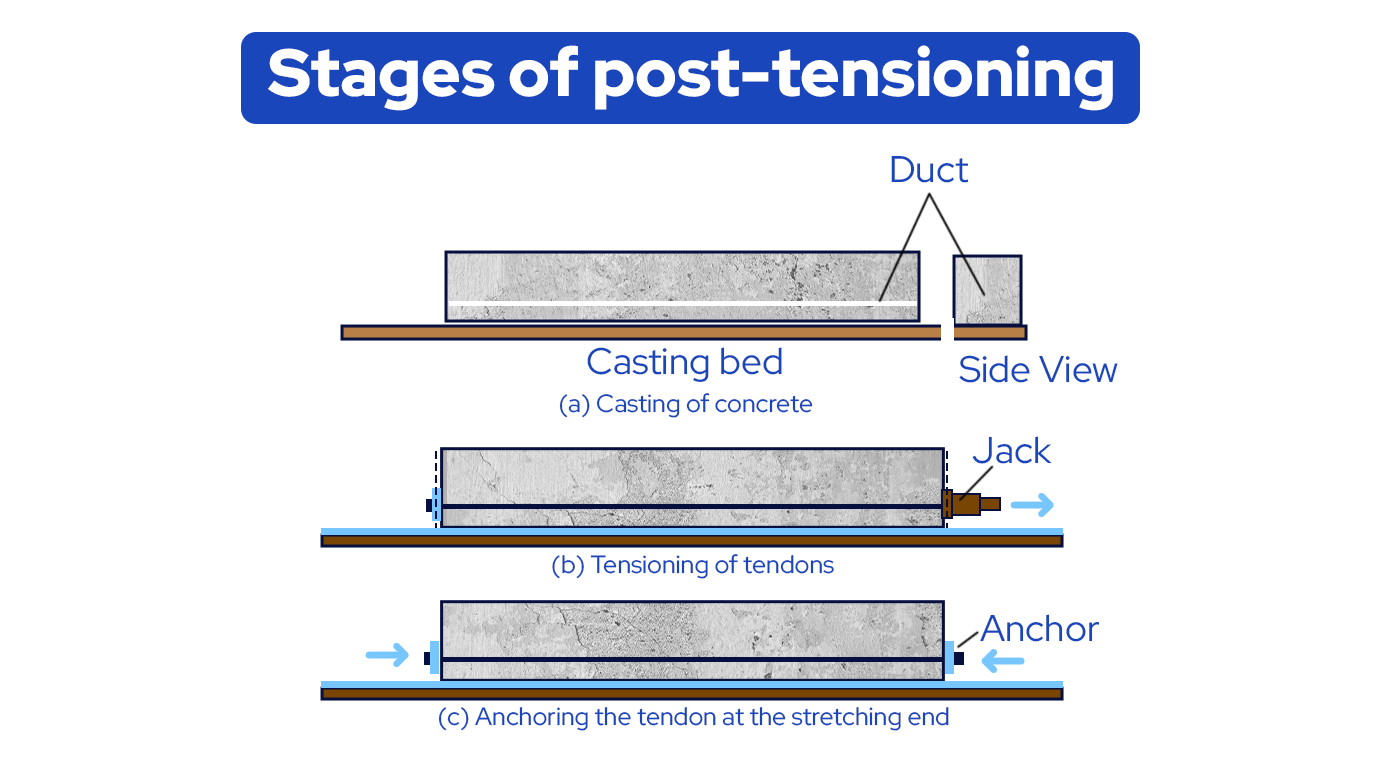

Post-tensioning

After the concrete has been cast and hardened in post-tensioning, the steel tendons are used to tension the concrete.

Two main operations are used for post-tensioning: tensioning steel wires or steel strands using hydraulic Jacks that stretch the steel strands while bearing on the ends and then replacing the jacks with permanent anchorages which bear on the member and maintain tension in the steel strands.

A tendon is made up of wires, Strands, or bars. Strands and wires are tied in groups, while bars are tied one at a time.

The steel tendons are used in the post-tensioning procedure. The concrete is cast before the formwork is completed. The tendons are protected from bonding with the concrete via waterproof paper wrapping or a metal sheath.

Bonded tendons are tendons that have been bonded to concrete. Unbonded tendons, which are left ungrouted or coated with grease, have no bond along their length.

What is the difference Between Pre tensioning and post-tensioning?

Pre-tensioning and post-tensioning are two different ways to prestress a heavy RCC beam structure. Both the processes have some differences in their methodology and approach that are:

1. Pre-tensioning is less expensive as sheathing is not used. Post-tensioning is more costly due to the use of sheathing.

2. Pre-tensioning is more durable and reliable, but post-tensioning's durability will depend on the Anchorage mechanism.

3. Pre-tensioning is more popular than post-tensioning because it's smaller and easier to transport structural elements.

4. Pre-tensioning is better for precast construction, as it is done in factories. In contrast, post-tensioning can also be done on-site and in factories.

5. Casting is different for pre-tensioning and post-tensioning concrete. Concrete is cast before tension is applied to the strands. In pretension, concrete is cast with tension cables enclosed in concrete. However, post-tension concrete plants are enclosed in a duct, and concrete is then cast.

6. Pretensioned concrete requires small sections, while post-tensioned concrete allows for the use of larger members. Long-span bridges are generally constructed using post-tensioning.

7. Products are modified according to the structure of post-tensioned concrete. However, similar structures can be prepared using pre-tensioned concrete.

8. Pretensioning loss is not greater (only about 15% in post-tensioned concrete), and it is not lower (around 18% in pre-tensioned concrete).

9. Moulds are used to make pre-tensioning members for prestressing concrete. Cables can be used in their place, while Jacks are used for stretching in post-tensioning.

10. Concrete is pre-tensioned with tendons before being placed in place. Post-tensioning concrete requires prestressing after the concrete has reached sufficient strength.

11. Pre-tensioning is a method that relies on the bonding of concrete and steel tendons. The post-tensioning concrete method, however, is designed to bear loads.