Prefab or Prefabricated construction is the process of manufacturing different components of a structure in a factory or manufacturing facility away from site and then transporting the complete set of components to the construction site for assembly of the structure. This is all referred to as Offsite Construction. Prefabricated construction solves several problems related to cramped, busy and dense urban environment construction sites. Transportation of material and equipment in the site area as well as on the site premises can be very troublesome, that would result in increased costs and extended timelines. Prefab construction is a perfect solution for all these problems. Offsite construction provides better provisions for planning and manufacturing building components in another place.

Prefabricated construction has changed the face of construction in the last few decades. Prefabricated materials are strong, financially viable and environmentally friendly. Prefabricated construction materials and products have better quality than in situ manufactured components. Prefabricated Construction has great design, high performance actions and quality controlled manufacturing procedures. Prefab construction is carried out in two main steps, manufacturing and transportation to sites for erection. In the first step, prefabricated materials are manufactured in the offsite factories or prefab construction units and in the second step, prefabricated materials are used in erection of the structure on site.

Benefits of Prefabricated Construction

Prefabricated construction is not only being used for huge structures but also for several other construction functions, that are:

- Prefabricated building materials such as concrete and steel sections are most commonly used in prefabricated construction of structures that have repeated use of a single type of building component.

- The need to transport concrete mix to construction sites and pumping wet over layoits in cramped construction sites is prevented by using prefab construction.

- Costs related to on site cutting and welding of steel sections as per different tasks and the risks associated with it is reduced by using prefabricated materials.

- Prefab construction is extensively used in housing colonies, apartments blocks, etc that have similar repeating patterns of offices blocks, warehouses and commercial buildings.

- Glass and steel are being produced in excess, in prefab construction units for huge structures.

- Prefabricated building materials for bridge structures are less costly than in situ construction of bridge components. Prefab construction used in bridges saves time and greatly reduces environmental impact.

- Not only does factory made prefabricated materials provide better assurance of quality because of the standard process being followed there regularly, but also provide consistent weather for production and streamlining of activities which improves job safety.

- Since prefabricated materials are constructed in specific factory spaces to provide materials to individual or multiple corporations, the waste generated is concentrated at a particular place that can be easily treated and safely dumped.

Challenges in using Prefab Construction Materials

As the prefabrication construction is still in its developing stage, using it can present some challenges and disadvantages, which are:

- Many risks are involved in prefabricated construction when compared to traditional construction methods. The reason being that huge components that are produced in offsite factories are left at the discretion of the offsite manager to conform to building regulations, therefore even the slightest mistakes can put the entire structure in danger. There is also a lot of risk involved in handling of these prefab componenta while transporting

- Since prefab construction is a rapid process, workers might be prone to committing errors due to intense time pressure.

- A set of standard prefabricated components are built as per the regular enquiry and demand. Sites the provision for customization in design for building components cannot easily be achieved by using prefab construction because of their regular shapes and design pattern. They lack detail and customization.

Though there are challenges that arise when using prefabricated construction materials, these disadvantages can be reduced or eliminated with the help of research and development of innovative properties and functions. Ways must be devised to overcome hurdles associated with using prefabricated construction processes for all small and large scale projects.

Prefabricated Construction in India

The prefabricated production in India was pioneered by government run Hindustan Housing Factory, which changed its name to Hindustan Prefab Limited(HPL) due the diversity of its prefab operations. Prefabricated Construction in India is majorly being used for large scale projects. In the last few decades the Indian Infrastructure and Construction sector has grown exponentially. Consequently the focus has moved from cost efficiency to time and capability. Many government construction schemes have assigned mass usage of prefabricated materials for cost efficiency and rapid construction. The Pradhan Mantri Awas Yojna(PMAY) aims to build 20 million houses for the urban poor. The Ministry of Housing and Urban Development along with the GOI has adopted many innovative prefab construction systems developed indigenously to accomplish this enormous task. Prefabricated construction cost in India is less than the traditional methods of construction in case of large scale projects and sometimes cost efficient in case of small scale projects.

Common Prefab Systems

Prefabricated materials consist of not only concrete and steel components but also different material systems. Some of the commonly used prefab systems are:

- Panelized Wood FramingThese systems comprise of long pieces of frames built from laminated timber and covered with plywood or some roof deck. These prefabricated materials are generally used in construction of roofs.

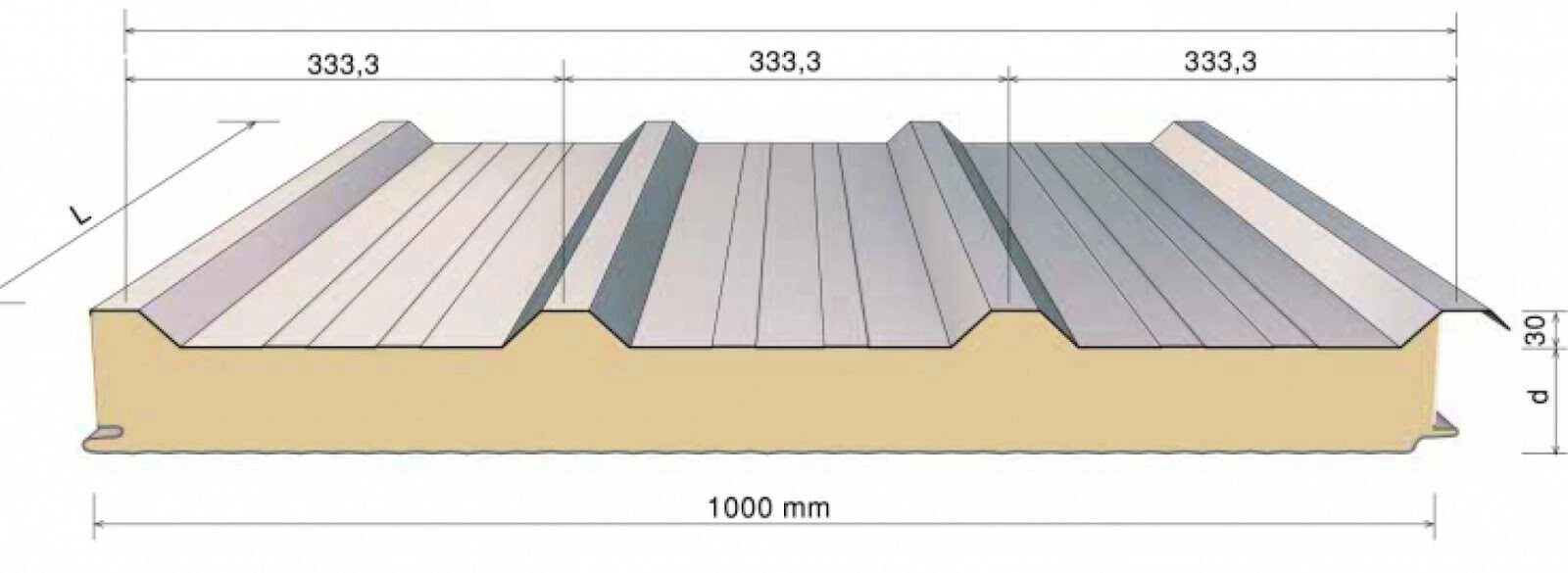

- Sandwich PanelsThese consist of an insulating core material that is covered with thin facings of materials on the two sides stuck firmly. The insulating materials and facing materials used can be foam, paper, cloth rubber, etc and concrete, plywood, stainless steel, etc respectively.

- Steel FramingStrong and durable steel framing systems are made from steel that can be used to construct buildings.

- Timber Framing- Timber framing panels are used as prefabricated materials for construction of timber houses, not much common in India.

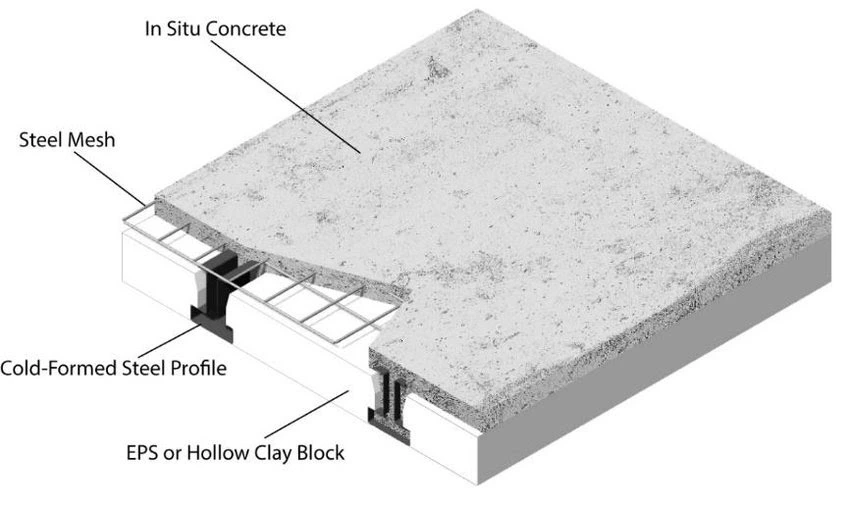

- Concrete SystemsPrefabricated construction using concrete components provides more versatility and saves time. In Spite of being heavy, concrete components are robust in usage that also improve the aesthetics of the structure.

- Modular SystemsThese systems are entirely built from prefabricated building materials from the offsite factories. The components are transported to the structure construction site and then simply connected to construct it.

Prefabricated construction offers benefits like time saving, site safety, sustainability and superior quality construction. Other benefits include site safety, waste reduction, improved air quality, quality management, etc. Prefab construction does have several benefits, but only for huge volumes of construction.

Prefabricated construction components need to be transported to construction sites at specific points scheduled to avoid delay in any as well as avoid space consumption by the components if transported earlier than required. This process can be easily monitored and directed using

Powerplay application. Powerplay is one of the most recently developed construction management tools that provides a unique management experience for services related to construction sites.