What is Ferrocement, its Applications and Advantages in Construction?

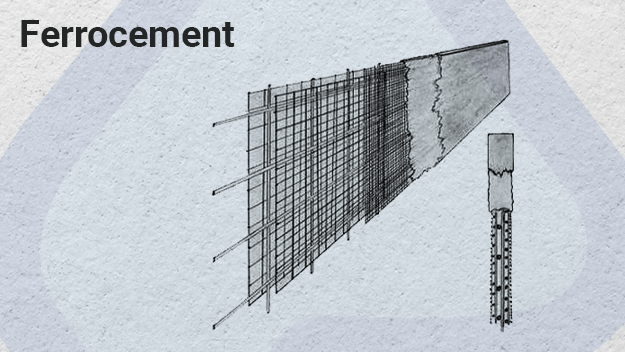

Ferrocement is a construction material, specially reinforced cement concrete(RCC), comprising cement mortar and wire meshes. Ferrocement is widely used in the construction industry due to its low self-weight and because it does not need skilled workers and standard frameworks.

Ferrocement was first developed in 1940 by Italian architect P.L.Nervi. Its constituents are manufactured with the help of a proper machinery setup, and the time required to execute a project based on ferrocement is relatively less. It ensures the quality of structures built using ferrocement. With time, ferrocement in construction has become widespread, especially in the last twenty years.

Engineering properties of Ferrocement

Ferrocement has high fracture resistance, tensile strength, flexural strength, toughness, impact resistance and fatigue resistance. It is a thin-wall type of reinforced concrete that includes cement mortar layered with continuous and comparatively small diameter mesh.

Ferrocement structures can withstand large strains around mesh reinforcements. The amount of strain capacity of the ferrocement structure depends on the distribution and subdivision of the mesh reinforcement throughout the concrete mass.

The dimensions of the wire mesh used in ferrocement usually range from 0.5mm to 1mm in diameter, spaced at intervals ranging from 5mm to 25mm in the concrete volume. The amount of mesh ranges from 1% to 8% of the total volume of the structure, and the thickness of the ferrocement section ranges from 10mm - 40mm. The cover for the outermost wire layers ranges from 1.5mm to 2mm.

What are the properties of ferrocement?

Ferrocement is a highly efficient material due to the following properties:

-

Ferrocement is an exceptionally versatile material form of reinforced cement concrete.

-

Due to the use of many wire meshes having small diameters uniformly throughout the cross-section, ferrocement is used to build a thin reinforced cement concrete.

-

The mesh used with cement mortar is generally made of metal or suitable material.

-

Portland cement is used instead of concrete to form the ferrocement mix.

-

The ferrocement structure's strength depends mainly on the quality of the cement mortar mix and the quantity of reinforcing materials used.

What are the constituent materials used in ferrocement?

Apart from cement and reinforcing steel mesh, other materials used as constituents for ferrocement are fine aggregate, admixture, mortar mix, skeletal steel, coating and water.

Advantages of Ferrocement

Ferrocement is highly advantageous due to the following benefits:

-

The raw materials used for preparing the ferrocement mix are easily available in most regions.

-

Ferrocement can be moulded into any shape or size. It is more suitable than RCC for this purpose.

-

The skill level required for working with ferrocement is not very high.

-

With ferrocement, the ease of construction and life of structure increases, whereas the weight is also reduced.

-

The cost of the constituent materials is also low.

-

Ferrocmenet structures have better resistance to earthquakes.

Disadvantages of Ferrocement

Even if ferrocement is used widely across the construction space, it has some disadvantages that are:

-

Ferrocment structures are easily punctured when pointed objects collide with them.

-

The reinforcing mesh is more prone to corrosion as it is not completely covered with mortar.

-

Fastening bolts, screws, welding and nails to ferrocement structures is not easy.

-

Even if the skill level is low, ferrocement procedures require more labourers.

-

Due to large labour requirements, the cost of unskilled and semi-skilled labourers increases the project's total cost.

-

The tying of rods with the mesh is rather tedious and time-consuming.

What are the steps involved in ferrocement construction?

Ferrocement construction is achieved in the following steps:

-

Manufacture of the skeletal framing system

-

Application of meshes with rods

-

Plastering of the structural surface

-

Curing of the final structure

Applications of Ferrocement

Ferrocement is used for housing, water supply, sanitation, marine, agricultural, rural energy, and permanent formwork structures.

Marine applications

Marine application of ferrocement finds use in constructing boats, finishing vessels, barrages, docks, floating buoys and fuel or water tanks. Ferro cement is advantageous for marine applications because it fulfils the marine requirements of water tightness, slight thickness, impact resistance and lightweight.

Water Supply and Sanitation applications

Ferrocement is used to construct water tanks, well casings, lining of swimming pools, sedimentation tanks and septic tanks.

Agricultural applications

In constructing agricultural structures, ferrocement is widely used to build silos, water tanks, pipes, grain storage bins, irrigation channels and linings of underground pits.

Housing applications

Ferrocement is used in housing applications for constructing shelters, sheds, dome structures, wall panels, housing elements made of precast, sandwich panels, permanent formwork, hollow core slabs, corrugated roofing sheets and repair or rehabilitation of existing structures.

Rural energy applications

Nowadays, ferrocement is widely used for rural construction projects like biogas digesters and holders, solar panels and incinerators.

Permanent Framework applications

Ferrocement is used in manufacturing reinforced concrete, prestressed concrete, columns, slabs, beams and many such structures.