What are the Types of walls used in construction?

A wall is a structural element that divides a space into two spaces or rooms and provides shelter and safety. The walls can be divided into two types: inner walls and outer walls. Inner walls allow for the protection of the house, and outer walls provide shelter. Partition walls, Interior Walls, or Inner Walls are known as inner walls. Outer walls are also known as exterior walls.

Types of walls in construction

The major types of walls used in construction are:

1. Load Bearing Walls 2. Drop Walls 3. Shear Walls 4. Retaining Walls 5. Brick Masonry Walls 6. Course Rubble Masonry Walls 7. Random Rubble Masonry Walls 8. Core Walls 9. Precast Walls 10. Parapet Walls 11. Curtain Walls 12. Compound Walls

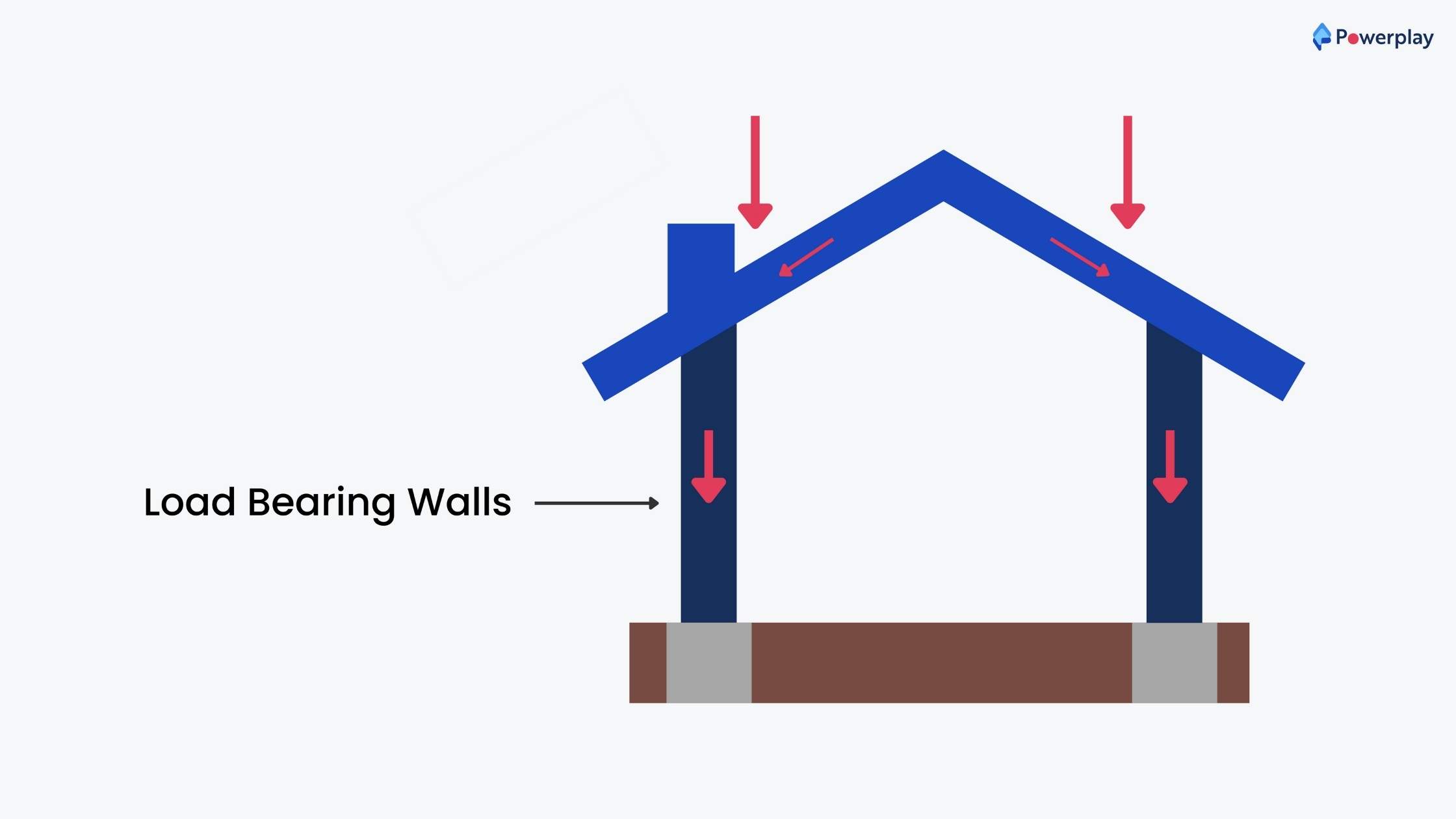

1. Load Bearing Walls

The name suggests that the entire building structure rests on walls and not columns. The load from the slab is transferred to the beams, then to the columns and walls simultaneously, and finally to the foundation.

The wall carrying the entire structure's weight, whether exterior or interior, is known as a load-bearing wall. For load-bearing walls, a strip foundation is used.

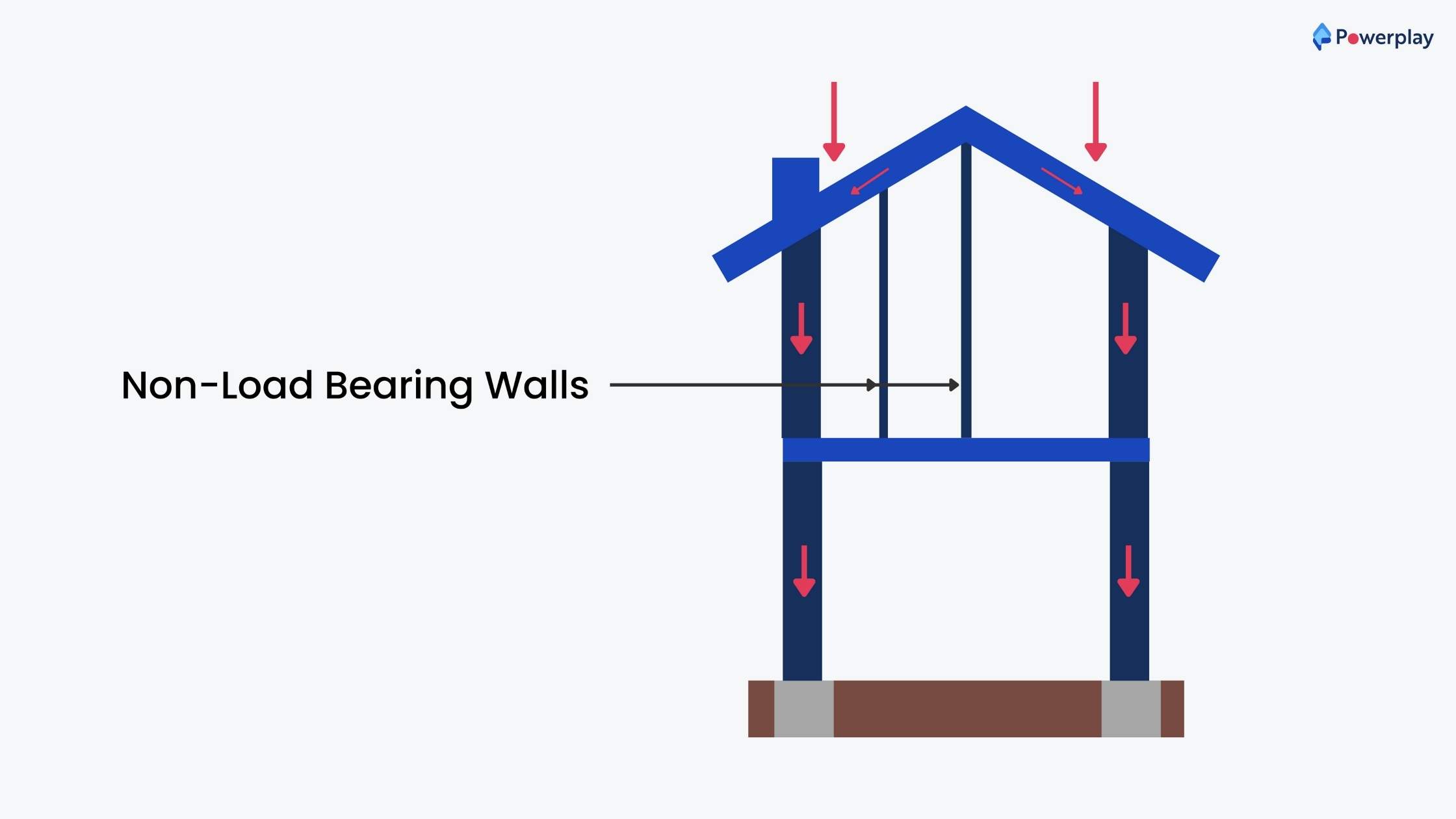

2. Non Load Bearing Walls

This wall is not designed to support roof or floor loads. It can therefore carry no weight from the structure above. The best example is the partition walls within a building. These walls are used to divide rooms and don't have any structural integrity. Without affecting the structure of the building, it is possible to remove or reduce non-load-bearing walls.

These walls can also be called Drop walls or Filling walls.

The thickness of Non-Load Bearing Walls is generally between 100mm and 125mm.

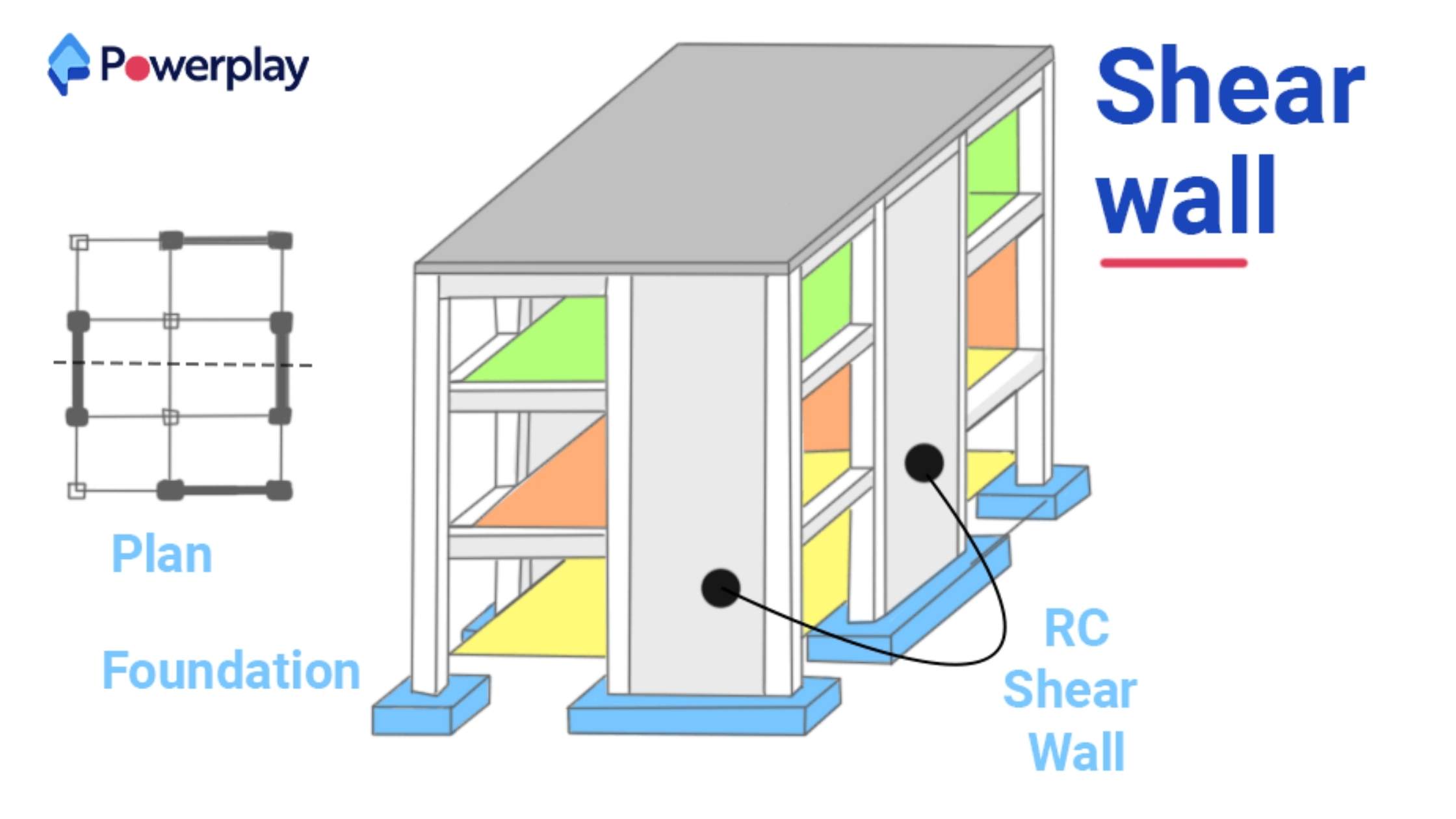

3. Shear Walls

The shear wall is the wall built around the water sump, lift pit, or staircase to retain the soil. Shear walls can bear two pressures, wind pressure and soil pressure, wind pressure and water pressure. Shear walls resist these forces. These walls can withstand the lateral forces exerted on the structure by wind, earthquake, or other lateral loads.

Let's take the overhead water tank as an example because it is built on high ground and is subject to wind pressure. Water pressure is created inside the tank by water in the water tank. A shear wall resists these forces without any deflection.

4. Retaining Walls

A Retaining wall is a wall that is designed to keep the ground at an uneven level on both its faces. Retaining walls are constructed around the plot to keep the soil at one end and the land from sliding on the other after earthwork is completed. You can choose to make a retaining wall from RCC.

Retaining walls can be classified into gravity, reinforced concrete, brick masonry, anchored, and stone retaining walls.

5. Brick Masonry Walls

A brick masonry wall is a wall made with bricks. The bricks are joined together using masonry. Brick walls can be as thick as 20cm or 10cm thick.

The 20cm wall is used for the outer and inner walls, and the 10cm wall is used.

The brick wall should not exceed 4m in length. A column with RCC is built if it exceeds 4m.

6. Course Rubble Masonry Walls

Course Rubble Stonemasonry wall is made with regular-sized stones that are well-finished and dressed. This wall is used to abut bridges, compound walls, or boundary walls.

7. Random Rubble Masonry Walls

A random rubble masonry wall is a wall made with irregularly sized stones. This wall uses more masonry than the Course-rubble stone wall.

8. Core Walls

The foundation is used to build the core wall. It then rises to the height of the building. This wall acts as a column. The core wall is designed to withstand the lateral forces exerted by wind, earthquake, or other lateral loads.

Core walls combine shear walls. To void the torsion effect, they are arranged in a core-like fashion and placed at the centre of the building.

9. Precast Walls

Precast walls are built by casting concrete into reusable molds, curing them and then finally transported to the site to be installed. As they are prepared in strictly in controlled conditions, precast walls have the least amount of defects. Not many companies develop this product currently in India.

This wall is best for areas with limited space and less labour. Precast walls are great because they can speed up the construction process.

10. Parapet Walls

This wall is built on the top floor to prevent people from falling off the roof. The parapet wall's height is generally around 3ft.

11. Curtain Walls

A Curtain Wall is a wall made with either glass, aluminium, or a steel frame. This wall is commonly used in hospitals, offices and other public buildings.

12. Compound Walls

A boundary wall is a wall built around the building to mark the boundaries of the plot.